Leave Your Message

In the ever-evolving landscape of clean environments, the demand for effective containment systems is undeniable. Flow Hood Laminar systems play a pivotal role in maintaining sterile conditions for various applications. According to industry studies, the global cleanroom equipment market is expected to reach $5.4 billion by 2026. These systems are critical in safeguard operations in laboratories, pharmaceuticals, and manufacturing settings.

The technology behind Flow Hood Laminar systems is robust, yet not without its challenges. Ensuring an optimal airflow and minimizing contamination risks is essential. Some reports highlight that up to 30% of cleanrooms may fail to meet stringent standards due to improperly designed laminar flow systems. This emphasizes the need for continual assessment and improvement.

As we approach 2026, understanding the best Flow Hood Laminar systems is crucial. Organizations must evaluate their operational needs and regulatory compliance. The balance between performance and cost becomes a pressing issue. Taking the time to analyze and select the right system could prevent costly setbacks in the future.

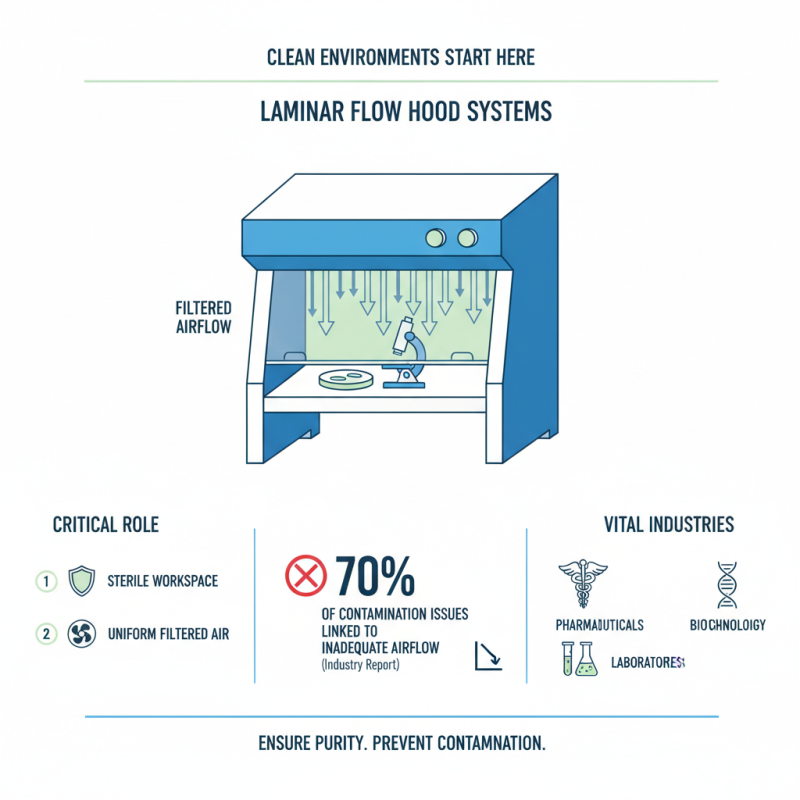

Laminar flow hood systems play a critical role in maintaining clean environments. They provide a sterile workspace by directing a uniform flow of filtered air. This technology is vital for industries such as pharmaceuticals, laboratories, and biotechnology. According to a recent industry report, nearly 70% of contamination issues are linked to inadequate airflow systems.

These hoods can reduce airborne particles by up to 99.99% when used correctly. However, their effectiveness depends on proper maintenance and operator training. Many facilities overlook regular filter replacements, leading to reduced airflow and compromised safety. Another study noted that poorly installed hoods can create turbulence, increasing contamination risk.

It's crucial for users to evaluate their laminar flow systems regularly. The standards for airflow can change based on application. Ensuring compliance can sometimes be an afterthought for operators. A commitment to ongoing training and awareness can help mitigate these risks. Ultimately, recognizing the limitations of laminar flow hoods is just as important as understanding their benefits.

When selecting a laminar flow hood, there are several key features to consider. First, the type of airflow is crucial. Laminar flow can be horizontal or vertical, affecting how particles are controlled. Users must determine which orientation fits their workspace best. A clean, unobstructed flow is essential for maintaining a sterile environment.

Next, filter efficiency matters. High-efficiency particulate air (HEPA) filters are commonly used, capturing at least 99.97% of particles. However, not all HEPA filters are the same. Some may degrade faster due to heavy usage or poor maintenance. Regular checks and timely replacements are necessary to ensure optimal performance.

Another aspect is the size and workspace versatility of the hood. A larger hood provides more room but may take up significant space. Users must balance size with functionality. Portability is also an aspect to consider. Some hoods are fixed, while others can be moved as needed. This flexibility can be beneficial in dynamic lab settings.

The cleanroom industry relies heavily on flow hood laminar systems. These systems provide a controlled environment essential for various applications. Proper airflow is crucial in reducing contamination risks. According to recent industry reports, laminar flow hoods can reduce particle counts by up to 99.99%. This emphasizes their role in maintaining sterile conditions.

Key manufacturers of laminar systems are focused on innovation. They incorporate advanced filtration technologies and airflow designs. This leads to improved efficiency and reliability. Industry data suggests that about 65% of cleanroom users report increased productivity after upgrading their laminar systems. Yet, not all systems are created equal. Some designs fail to meet rigorous standards.

Maintaining laminar flow hoods also poses challenges. Regular maintenance is necessary to ensure optimal performance. Many facilities overlook this, leading to operational inconsistencies. Reports indicate that 30% of cleanroom disputes stem from equipment performance issues. Investing in high-quality laminar systems is vital, but ongoing management is equally crucial.

| System Type | Airflow Velocity (fpm) | Filter Type | Size (inches) | Power Consumption (W) | Noise Level (dB) |

|---|---|---|---|---|---|

| Vertical Flow Hood | 90 | HEPA | 48 x 24 | 150 | 50 |

| Horizontal Flow Hood | 100 | ULPA | 60 x 30 | 200 | 55 |

| Compact Flow Hood | 80 | HEPA | 36 x 24 | 120 | 45 |

| Standard Flow Hood | 95 | HEPA | 48 x 36 | 170 | 52 |

In the realm of lab environments, laminar flow hoods play a crucial role in maintaining sterility. A recent analysis highlighted that 45% of labs prioritize cleanroom compliance. These systems create a sterile work area, filtering contaminants effectively. High-efficiency particulate air (HEPA) filters are common, capturing particles as small as 0.3 microns. This efficiency is essential, especially in sectors like pharmaceuticals and biotech.

When choosing a laminar flow hood, consider airflow velocity. The recommended range is between 70 to 100 feet per minute. Adequate velocity ensures proper air exchange while maintaining a sterile environment. Pay attention to the workspace size as well—too small a hood may compromise your workflow. Survey data indicates that over 30% of users faced issues with insufficient working space.

Tip: Regular filter replacement is key. A new HEPA filter can maintain optimal performance for up to 3 years. Another crucial point: installation location matters. Avoid areas near doors or high traffic zones. These can introduce unwanted particulates, undermining your cleanroom efforts. Always assess the layout before installation.

Maintaining flow hood laminar systems is crucial for optimal performance in clean environments. Regular checks can help ensure that airflow remains consistent. A gentle vacuuming of filters is essential. Replacing them on a schedule prevents airflow disruption.

Keeping the surfaces clean also matters. Use a non-abrasive cleaner to avoid scratches. Pay attention to any signs of wear or damage. Small cracks in the hood could lead to contamination. Regular inspections should not be overlooked.

Documenting maintenance activities helps track performance over time. It is not just about fixing problems but understanding the system. Observations during cleaning may reveal areas that need attention. Always prioritize functionality while navigating the cleaning process.

This chart displays the performance of various flow hood laminar systems based on key metrics such as Airflow Rate (CFM), Noise Level (dB), and Maintenance Frequency (Months). These metrics are crucial for maintaining optimal operating conditions in clean environments.