Leave Your Message

Choosing the right Paint Booth Filter Wall for your workshop is crucial. An effective filter wall helps improve air quality and enhances the finish of your work. However, it can be overwhelming to select the ideal option.

Consider the specific needs of your workshop. A high-efficiency filter may be advantageous for larger operations. Conversely, smaller setups might benefit from a simpler design. Each choice has its pros and cons.

It's important to evaluate factors like filter type, size, and airflow. The right filter wall can save time and improve productivity. However, if the decision is rushed, it could lead to mistakes. Reflecting on your specific requirements is essential for making a wise investment in your workshop's future.

When selecting a paint booth filter wall, understanding your workshop's air quality needs is essential. Different environments have unique air filtration requirements. Consider the size of your workshop and the type of painting you perform. For instance, a small space using water-based paints may require different filters than a larger area handling solvent-based applications.

Evaluate the contaminants present in the air. Are you dealing with dust, fumes, or VOCs? Measuring particle sizes can give you insight into the type of filtration you'll need. Some workshops overlook the importance of regular filter replacement. Old filters can become less effective, leading to poor air quality. It's not just about installing a filter; it's about choosing one that suits your specific circumstances.

You might want to engage with your team for their insights. They can provide feedback on current air quality. If team members experience irritation or discomfort, something's likely amiss. Taking the time to assess your needs—and not just settling for the first option—can lead to a safer, healthier working environment. Prioritize understanding the specific air quality challenges before making a decision.

When choosing paint booth filters, understanding the varieties available is essential. Some filters are designed for specific types of paint and application methods. For instance, particulate filters are great at trapping dust. They prevent contamination during the painting process. However, they might not protect against chemical fumes.

Another option is activated carbon filters. These filters absorb odors and harmful vapors, enhancing air quality in the workspace. But they have a limited lifespan. You'll need to replace them regularly to ensure effectiveness. Some users overlook this detail, which can lead to unsafe working conditions.

Consider the size and airflow capacity of your booth too. Adequate airflow ensures that fumes are efficiently removed. A filter that is too small may cause airflow issues. This can impact your overall painting quality. Research and test different filter types to find what works best in your situation. Making the right choice is crucial for safety and finish quality.

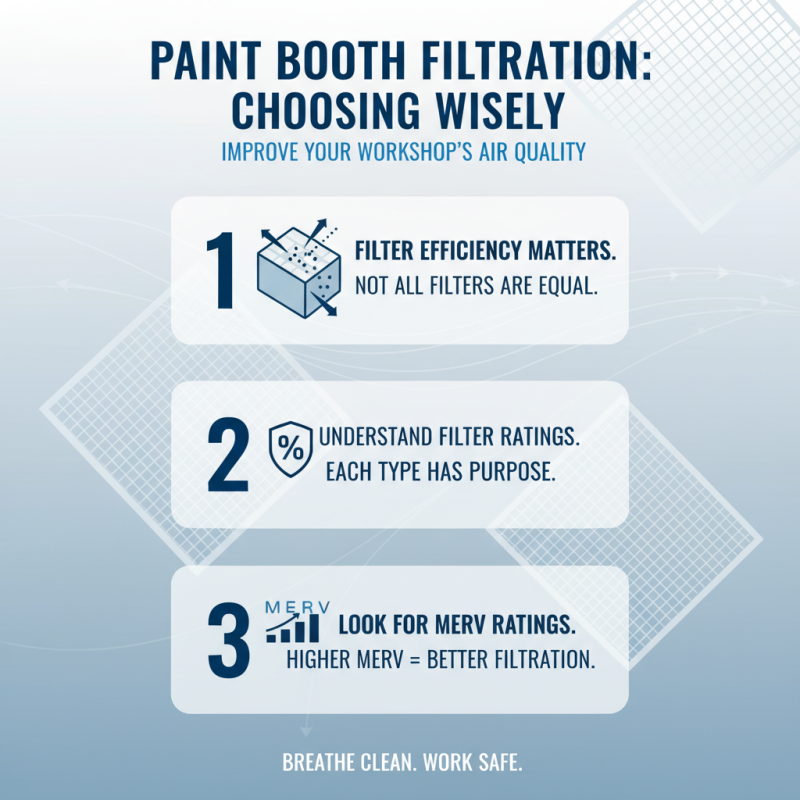

Choosing the right paint booth filter wall requires careful consideration of filter efficiency ratings. Not all filters are created equal. Each type of filter serves a different purpose and can vary in efficiency. Understanding these ratings is crucial for your workshop's air quality. Look for specifications like MERV (Minimum Efficiency Reporting Value) ratings. Higher MERV ratings generally indicate better filtration ability.

Efficiency isn't the only concern. You also need to think about airflow. High-efficiency filters may restrict airflow more than lower-rated options. This can impact your spray application and finish quality. Balance is key, and sometimes a lower MERV filter might be necessary to avoid airflow issues. Consider how often filters need changing too. A highly efficient filter that clogs quickly may end up costing you more in the long run.

You should also evaluate specific application needs. Some workshops deal with more toxic substances or particulates than others. A more robust filter may be needed in these cases. Don’t forget to assess the filter media itself. Some materials perform better than others under specific conditions. Reflecting on these factors will lead to a more informed choice.

When choosing a paint booth filter wall, assessing compatibility with your paint booth design is crucial. Different paint booth designs have specific requirements. Filters must fit well to ensure proper airflow. According to industry reports, nearly 35% of efficiency issues arise from improper filter installation. This emphasizes the need for careful consideration.

Filters can vary in thickness and material. Some are designed for high-volume applications, while others suit smaller operations. Consider the size of your booth and the type of paint used. A mismatch can lead to inadequate filtration and increased overspray, negating the benefits of your equipment.

Tips: Assess the airflow needs of your booth. Use a manometer to measure airflow before making decisions. Regularly check filter performance to ensure they meet design standards. Great performance starts with the right fit. A poorly matched filter can increase maintenance costs by up to 50%. This highlights the critical balance between cost and effectiveness in filter selection.

| Filter Type | Efficiency Rating | Recommended Applications | Dimensions (inches) | Replacement Frequency (months) |

|---|---|---|---|---|

| HEPA Filter | 99.97% | Fine particulates, fumes | 24 x 24 | 6 |

| Pleated Filter | 85% | Dust, pollen | 20 x 20 | 3 |

| Activated Carbon Filter | High Odor Removal | Chemical vapors, odors | 30 x 30 | 4 |

| Synthetic Filter | MERV 13 | Paint spray, general debris | 24 x 48 | 2 |

When managing a paint booth, regular maintenance of filter walls is crucial. Filters capture dust and contaminants, ensuring a clean environment. However, neglect can lead to inefficiency. Clogged filters reduce airflow, forcing equipment to work harder. This can increase energy costs and compromise quality.

Replacing filters is not just about routine; it involves monitoring performance. Check filters weekly for signs of saturation. If you notice discoloration or visible debris, it’s time to change them. Timing is key. Replacing them too late can damage the equipment and lead to costly repairs.

Tips: Keep a maintenance log. Record when filters are cleaned or replaced. This helps in recognizing patterns and planning ahead. Also, consider having a backup supply of filters. Being prepared can save time during unexpected issues. Reflect on the impact of your choices; a little effort goes a long way in maintaining a productive workshop.