Leave Your Message

In the world of automotive and industrial painting, choosing the right Spray Booth Filter is crucial. Data from the Environmental Protection Agency (EPA) indicates that approximately 15% of paint-related emissions can be minimized with effective filtration. According to John D. Reynolds, a leading expert in air quality solutions, “Investing in quality Spray Booth Filters not only improves air quality but also enhances the overall finish of your work.”

The market for Spray Booth Filter options has grown significantly, with numerous choices available to meet diverse needs. Each filter type offers distinct advantages and shortcomings. When selecting filters, it’s vital to balance performance with budget constraints. As technology advances, the efficiency of filters is continuously improving, yet some may overlook the importance of regular updates to their systems.

The right filter can dramatically influence paint application and compliance with regulations. Many businesses struggle with finding the perfect fit, leading to suboptimal choices. This challenge highlights the need for careful consideration. As the industry evolves, one must remain vigilant and adaptable in sourcing the best Spray Booth Filter options for specific requirements.

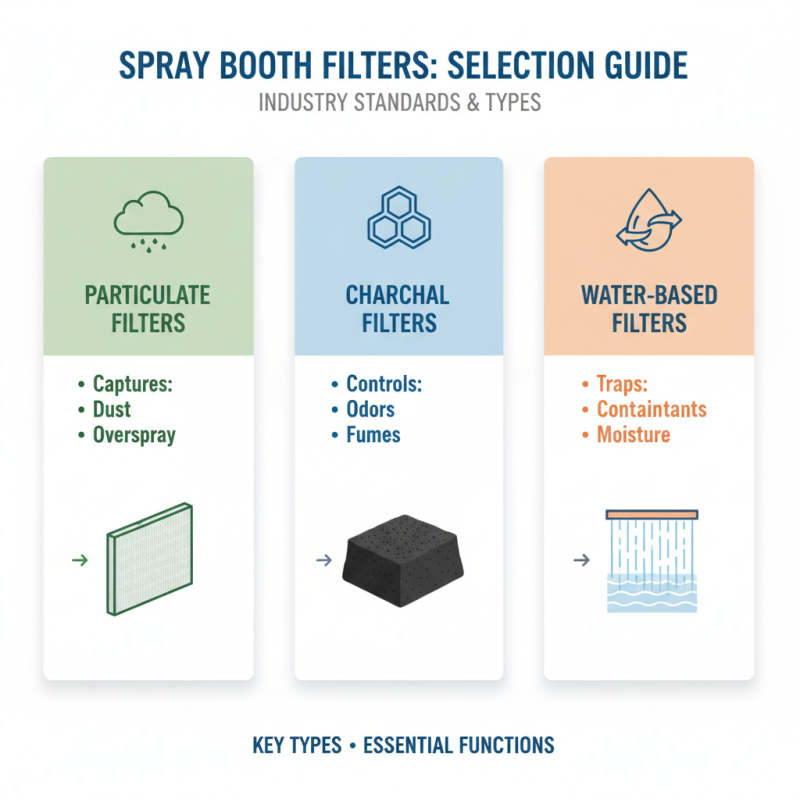

When selecting spray booth filters, understanding the industry standards and types is essential. There are various filters, including particulate, charcoal, and water-based filters. Each type serves a unique purpose. Particulate filters capture dust and overspray effectively. Charcoal filters help control odors. Water-based filters use moisture to trap contaminants.

It's crucial to assess your specific needs. For instance, a busy shop may require high-capacity filters. These filters must be changed regularly. Neglecting this can lead to reduced air quality. This decreases efficiency and increases risks.

**Tip:** Always check your filters. A clogged filter can cause issues. Monitor their condition and replace them as necessary.

Consider local regulations too. Different regions may have specific requirements for spray booth filters. Compliance is vital for your operation. Failing to meet standards can lead to penalties.

**Tip:** Stay informed about changes in regulations. Keeping up with updates can ensure your business remains compliant. Additionally, it's beneficial to consult with industry professionals. They can offer advice tailored to your situation.

Choosing the right spray booth filter is fundamental for optimal performance. When selecting a filter, consider its efficiency rating. A higher rating means better filtration but may come with increased resistance. This can affect airflow. Balance is key; efficiency should not compromise your operations.

Next, think about the type of materials you are working with. Some filters excel in catching larger particles, while others are better at trapping fine particulates. This can impact the quality of your work. Take into account the specific requirements of your task. Are there specific contaminants to target? Understanding these details can guide your choice.

Don’t forget to evaluate the filter's lifespan. Some filters might require frequent changes, adding to costs and downtime. Look for filters that can hold up well in your environment. Remember, the cost isn’t just about the purchase price. It includes maintenance too. Reflect on these aspects carefully before making a decision.

This chart illustrates the effectiveness of different types of spray booth filters based on their filtration efficiency and airflow resistance. The data reflects the performance ratings on a scale from 1 to 10, with 10 being the best. Choosing the right filter is crucial for maintaining air quality and optimizing booth performance.

When choosing spray booth filters, material efficiency and durability are key factors. Different materials offer varying levels of filtration. For example, synthetic media often provides excellent filtration while lasting longer than traditional materials. However, synthetic filters might be costlier upfront. They require a balance between performance and budget considerations.

Another option is fiberglass filters. They’re generally more affordable but may not capture all contaminants effectively. These filters need frequent replacement, which can lead to higher long-term costs. It's important to weigh the initial savings against potential waste. Some users overlook this aspect.

Performance can also vary under different conditions. Humidity and temperature fluctuations affect how filters perform. Regular monitoring and maintenance are essential for optimal efficiency. A well-maintained filter system operates better and lasts longer. Yet, many professionals overlook simple maintenance tasks. Making choices based on durability can reduce operational challenges over time.

| Filter Material | Efficiency (%) | Durability (Hours) | MERV Rating | Cost (per unit) |

|---|---|---|---|---|

| Polyester | 85 | 200 | 8 | $15 |

| Fiberglass | 90 | 150 | 10 | $12 |

| Carbon | 95 | 100 | 11 | $25 |

| Synthetic | 88 | 250 | 9 | $20 |

| HEPA | 99.97 | 300 | 16 | $50 |

Proper filter maintenance is crucial for optimal spray booth performance. Filters trap harmful particles and aerosols. When they become clogged, airflow decreases. This can lead to poor coating finishes. It may also increase the risk of fire hazards. Regular checks can ensure filters are replaced or cleaned timely.

Neglecting filter care can have serious consequences. A dirty filter may cause equipment strain. It can result in higher operational costs. In the worst cases, it compromises worker safety. Visible dust build-up is a sign. But issues can lurk beneath the surface. Often, we underestimate the impact of filters.

Routine maintenance will improve booth efficiency. It enhances the quality of the air in the facility. Without it, you risk damaging both the equipment and the product quality. Think of filters as the lungs of your spray booth. If they don’t function well, nothing else can. Consider setting a maintenance schedule to promote consistency. This simple action could protect both the environment and your investment.

In the world of spray booth operations, regulatory compliance remains crucial. Filters must meet specific environmental guidelines to ensure air quality and safety. Many industries rely on efficient and effective filtration systems. Harmful emissions can damage both the environment and public health. This makes choosing the right filter essential.

Not all filters are created equal. The effectiveness can vary significantly based on material and design. Some might capture larger particles but fail against smaller toxins. It's critical to review filter specifications. Are they compliant with local environmental regulations? This question can be overlooked when making purchases.

Regular testing and monitoring of filters are necessary. Performance can degrade over time, and regular checks can indicate when changes are needed. Sometimes, budgets constrain the best choices. However, cutting corners can have lasting impacts. Assess and reflect on the balance between cost and compliance; it’s a fine line to walk.