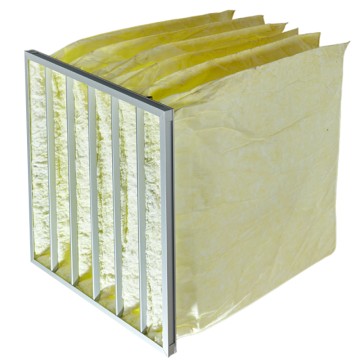

Paint Booth Intake Filter

Key Benefits

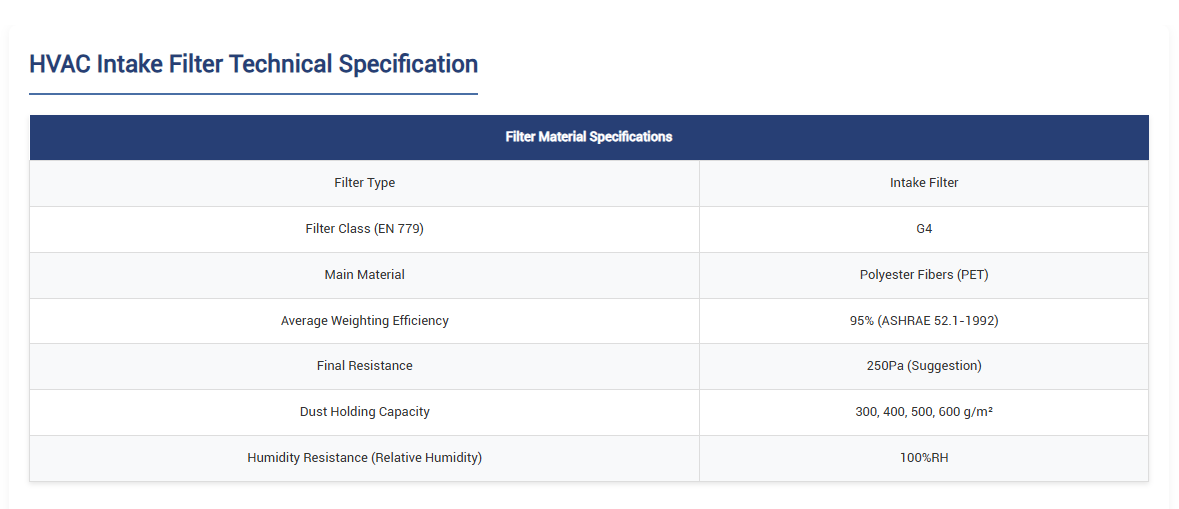

Primary Function: To protect equipment and secondary filters by capturing large particles (dust, dirt, pollen).

Unique Design: Features a tacky/adhesive surface that improves particle retention and filtration performance.

Construction: Made from high-quality polyester synthetic fibers reinforced with a rigid wire frame for stability.

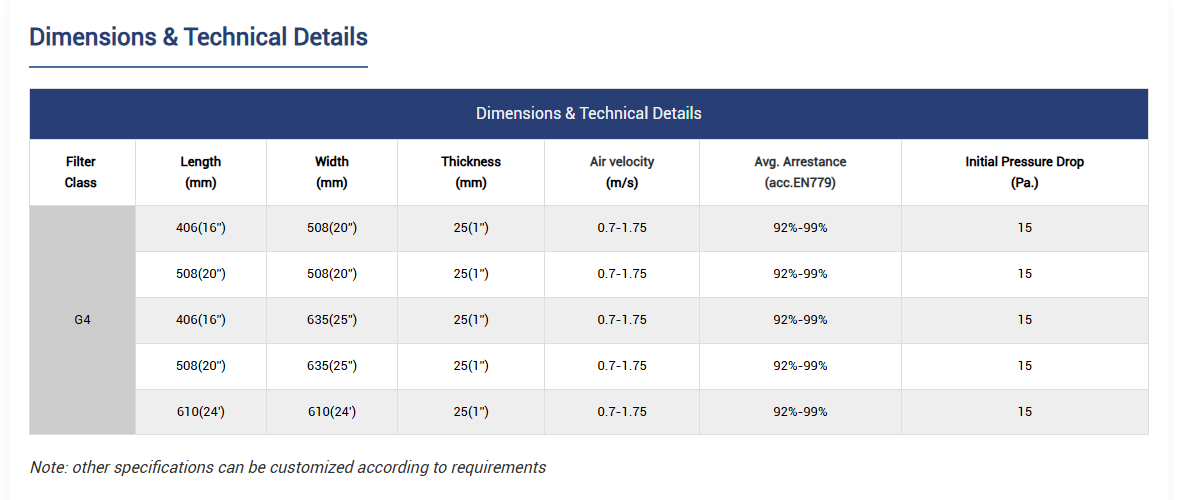

Efficiency Grades: Typically rated G3/G4 (European Standard) or MERV 5/6 (ASHRAE Standard), placing it in the coarse to lower medium efficiency range.

Performance:

High Dust-Holding Capacity: Can hold a large amount of dust before needing replacement.

Low Pressure-Drop: Designed to allow air to flow through easily, which helps the system run efficiently and saves energy.

Durability: Can withstand temperatures up to 80°C.

Ease of Use: Designed for simple installation in standard ventilation equipment.

Applications

This type of filter is versatile and used in various settings:

1. Paint Booths: The name implies its critical use here. It captures overspray and particulates to ensure a clean painting environment and protect finer final filters.

2. HVAC Systems: Used in residential and commercial heating and cooling systems to improve indoor air quality and protect the HVAC unit.

3.Industrial Environments: Ideal for dusty workplaces like workshops, warehouses, and manufacturing plants.

4. Public Buildings:Used in schools, libraries, and offices to maintain a healthy, dust-free environment.

Why This Filter is Important

In a system like a paint booth, this intake filter acts as a pre-filter. By capturing the bulk of the larger particles first, it:

Protects expensive equipment from wear and damage.

Extends the life of more delicate and costly secondary high-efficiency filters downstream.

Ensures efficient operation by preventing the system from getting clogged too quickly.