01

High Temperature H13 HEPA Filter

Main Features

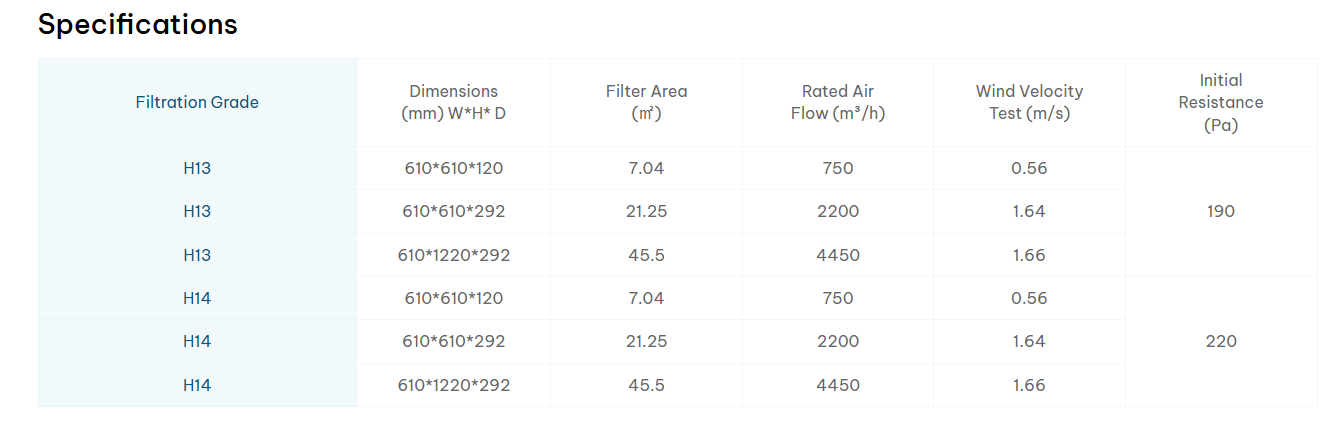

1. Filtration Efficiency: High-temperature HEPA filters capture at least 99.97% of particles as small as 0.3 microns. This level of efficiency ensures effective removal of even the tiniest air pollutants, maintaining the high air quality standards necessary for sensitive environments.

2. High temperature resistance: These filters can operate effectively in a temperature range of 250°C to 350°C (482°F to 662°F). They can withstand even higher temperatures to meet demanding application requirements, making them ideal for industries that require reliable performance in extreme high temperature conditions.

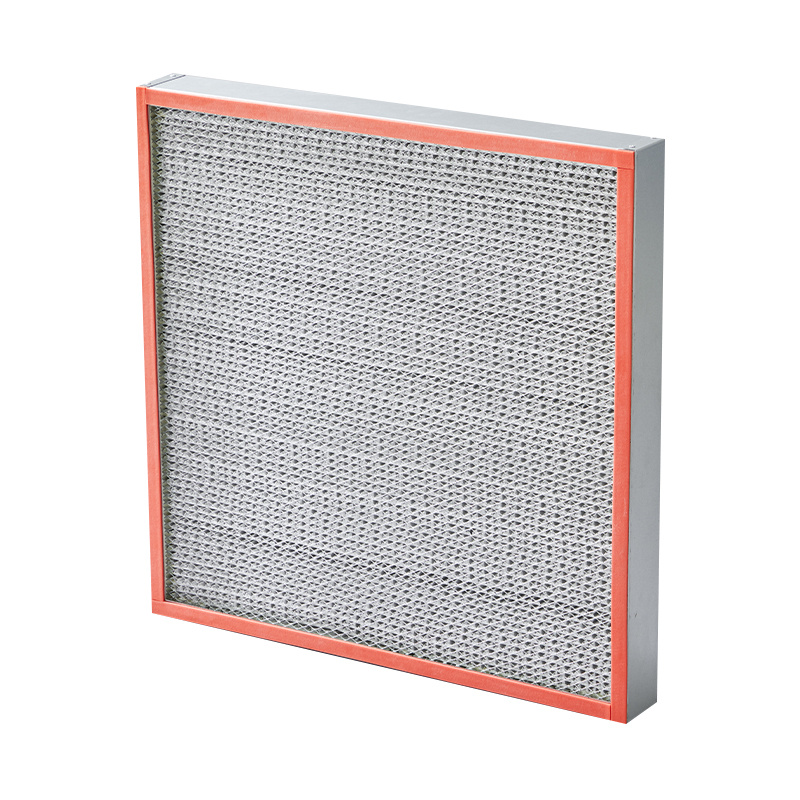

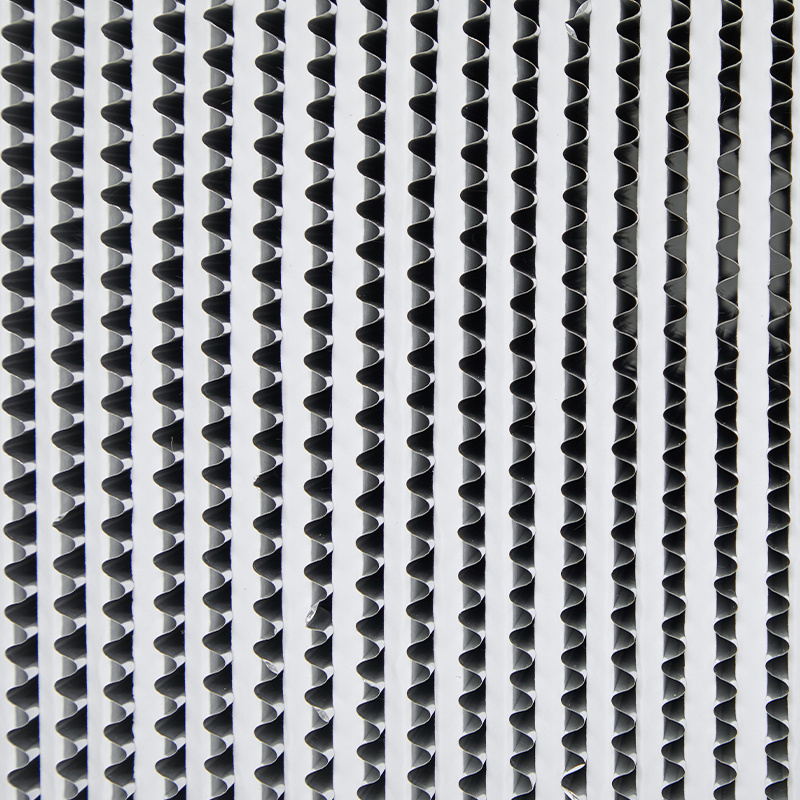

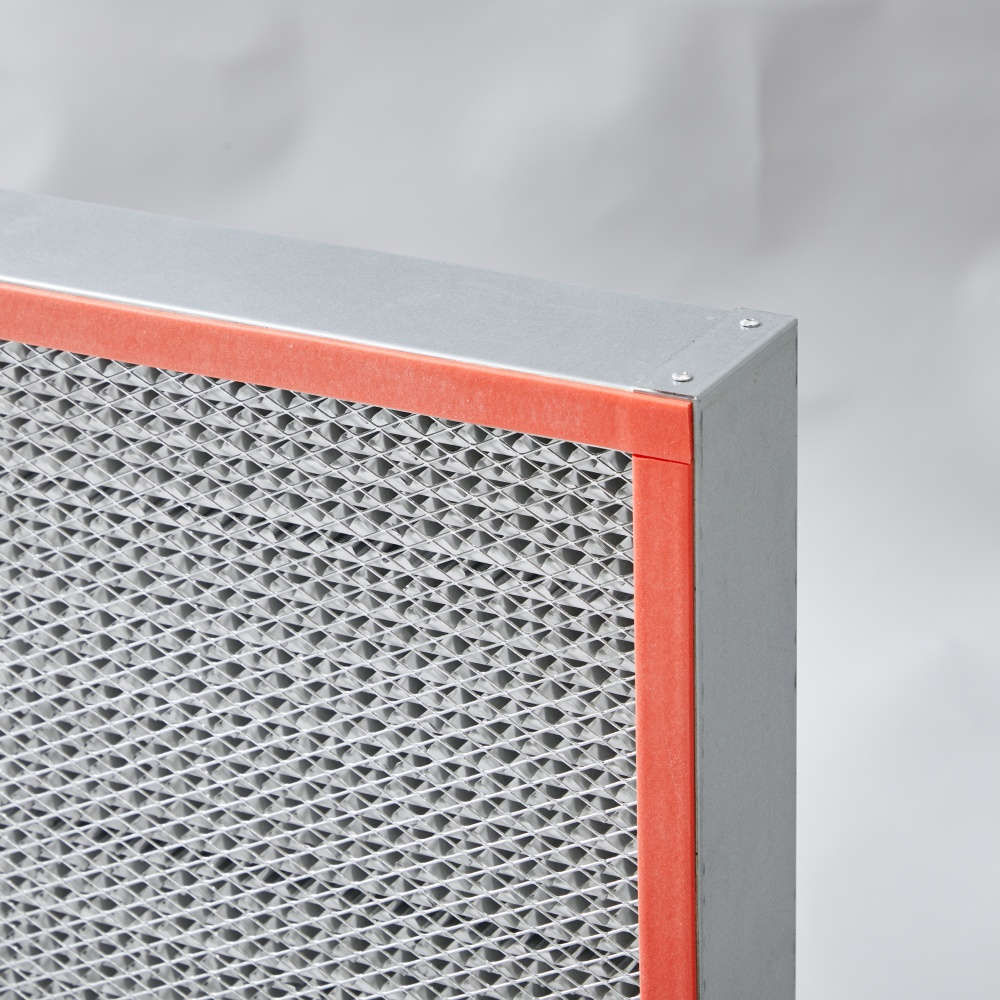

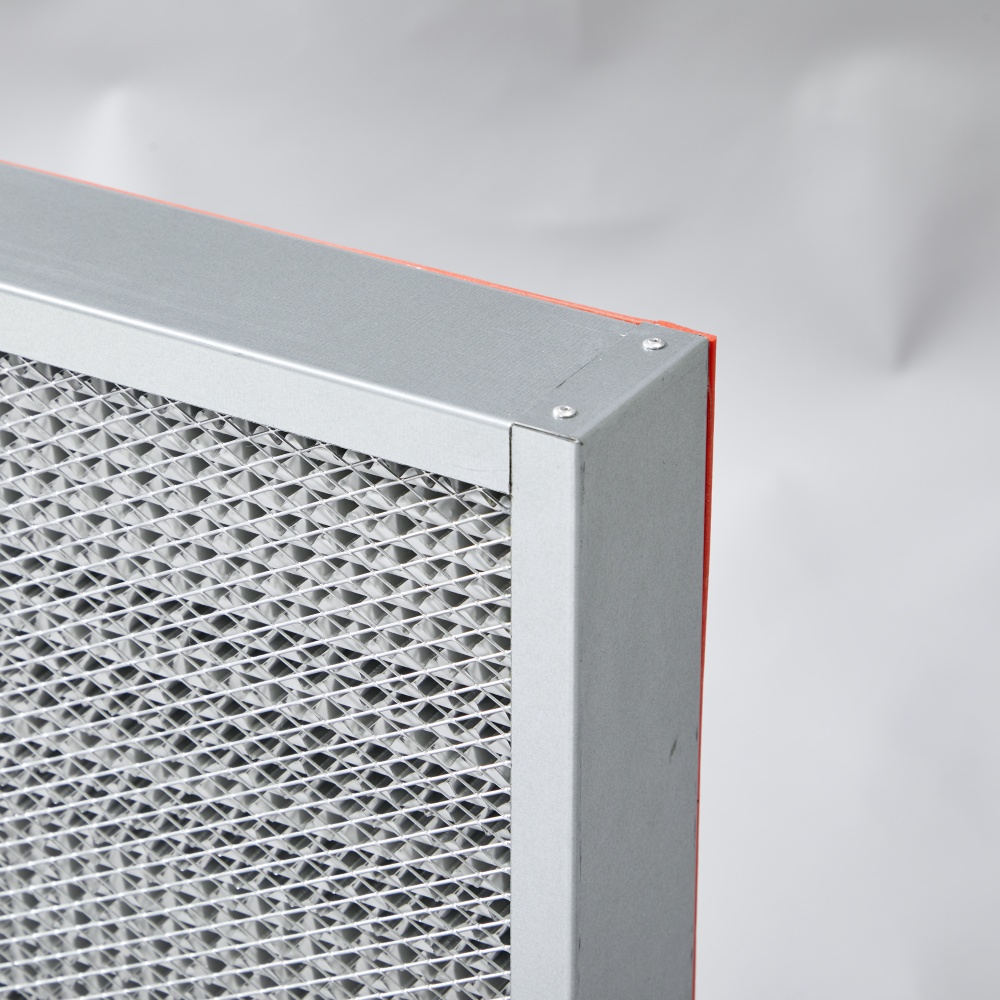

3. Durable Construction: The filter features a stainless steel frame, heat-resistant gaskets, and specialized filter media that withstands thermal stress without compromising filtration performance. This durable construction ensures longevity and reliability, even in the most challenging environments.

4. Filter Grade Options: A variety of filter grades are available, including M5, M6, F7, F8, F9 and MERV grades from 9 to 15. This range provides options for different filtration needs, enabling users to select the right filter based on specific air quality requirements.

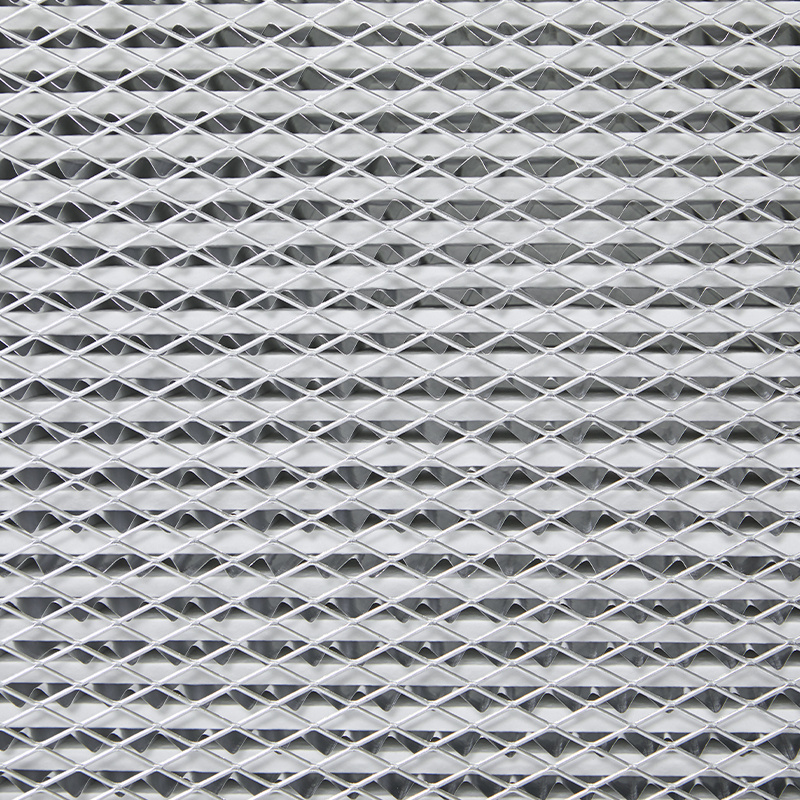

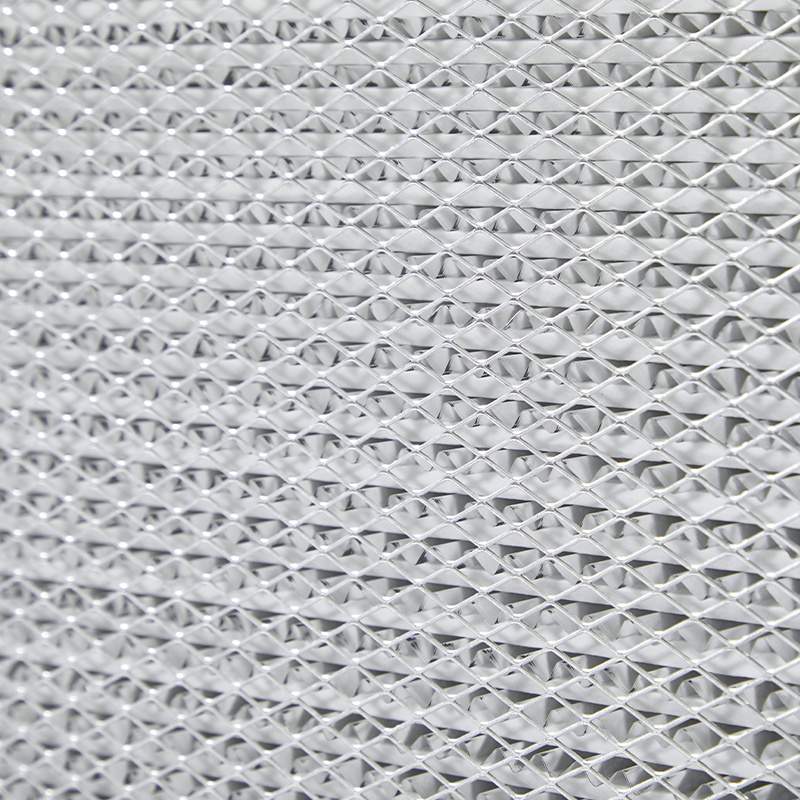

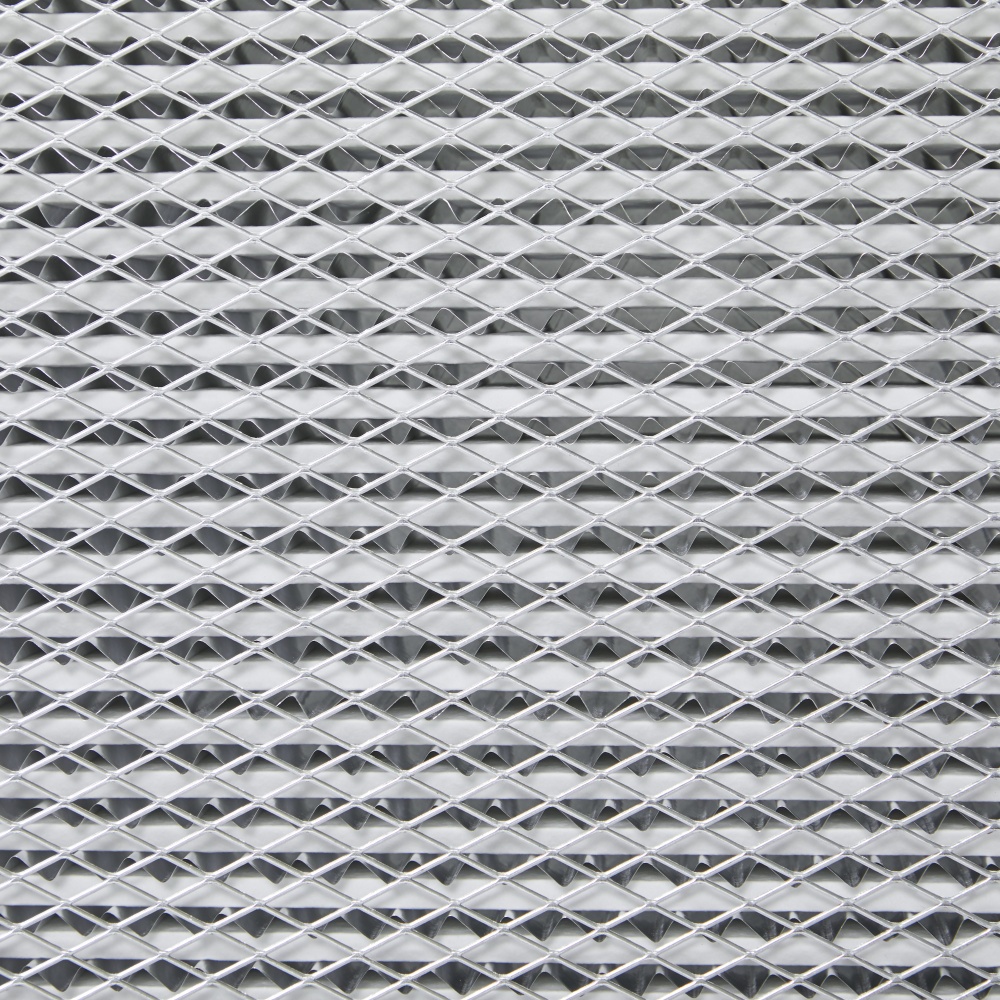

5. Filter Material: These filters are made of ultra-fine glass fibers for greater filtration efficiency and durability. The glass fiber material enhances the filter's ability to capture particles while maintaining airflow, ensuring optimal performance.

6. Frame Options: Users can choose between galvanized steel or aluminum frames, both of which provide stable support and long service life. The choice of frame material can be customized to specific application needs, ensuring compatibility and durability.

7. Secure Seal: The filter is designed with a secure seal and gasket to prevent air bypass and leakage. This feature is critical to ensure optimal filtration performance because it guarantees that all air passes through the filter media without leaking out of the edges.

application

High temperature HEPA filters are used in a wide variety of industries, including:

Automotive Industry: These filters are critical to keeping the air clean during the manufacturing and assembly processes, as contaminants can affect product quality and worker safety.

Aerospace: In aircraft and aerospace applications, maintaining air quality is critical to both safety and performance. High temperature HEPA filters help ensure the air is free of harmful particles.

Pharmaceutical and Biotech Centers: These filters are essential for maintaining sterile conditions in drug manufacturing and research environments, where even slight contamination can have serious consequences.

Laboratories and Research Facilities: High-temperature HEPA filters protect sensitive experiments and equipment from airborne contaminants, ensuring the integrity of research results.

Food and Beverage Production: In food processing environments, maintaining air quality standards is critical to preventing contamination. These filters help ensure the air remains clean, contributing to food safety.

In summary, high temperature HEPA filters are essential in industries that require superior filtration and high temperature resistance. They maintain high air quality even at extremely high temperatures, making them a reliable choice for a variety of applications. By investing in these advanced filters, businesses can ensure compliance with industry standards, protect sensitive processes, and create a safer working environment for employees.