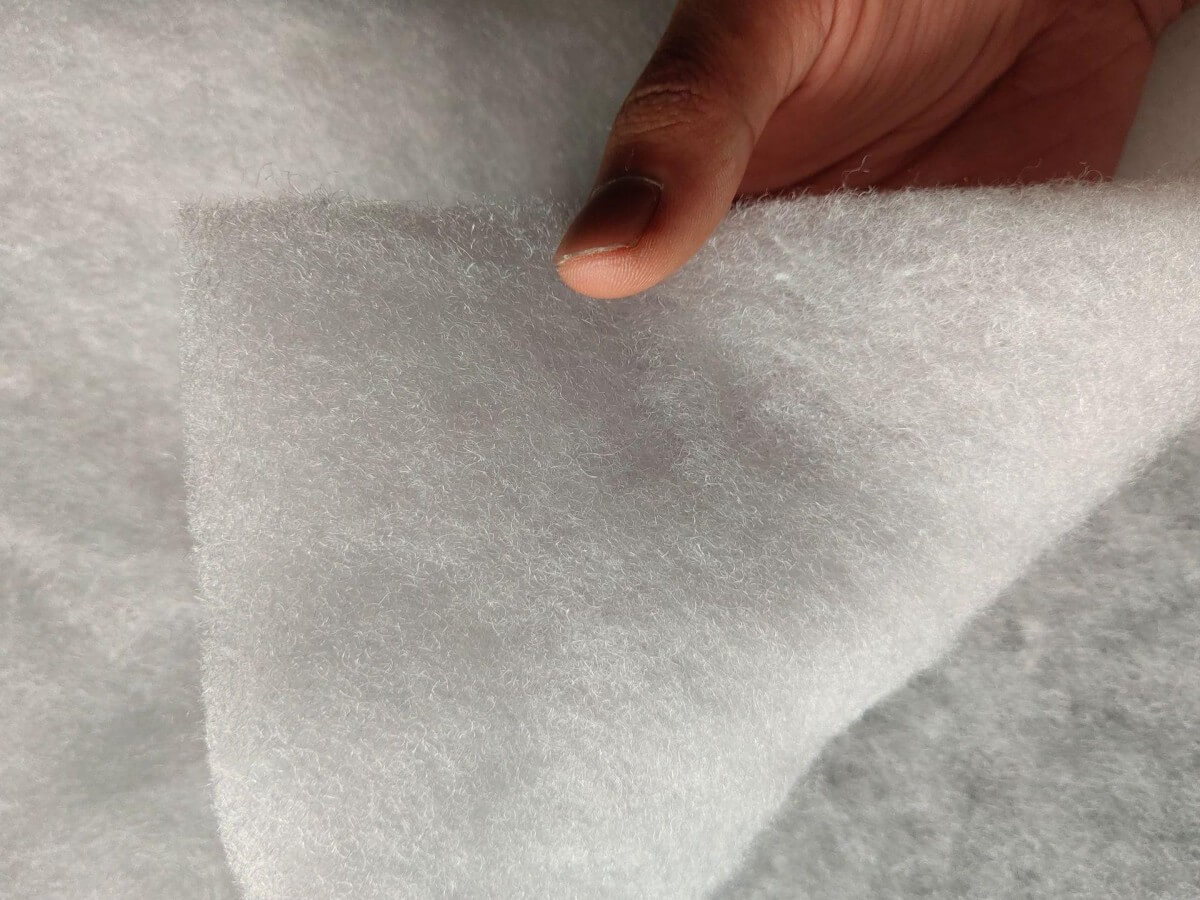

How to choose air filtration materials

As industrial air pollution becomes increasingly serious, the role of air Filter Cotton is becoming increasingly important, especially primary filter cotton. This filter is not only used in general ventilation systems to meet the requirements of indoor hygiene or process dust removal, but also used as a pre-filter in the clean room air supply system to capture larger dust particles first, thereby reducing the load of subsequent primary air filter cotton and extending the service life of the fine filter device. Today, I will introduce the three key points that air filter cotton must meet.

1. Meet the sanitation standards in the building: This is a common requirement for industrial and public buildings. Air filter cotton is used in general ventilation and air-conditioning systems to ensure indoor cleanliness and comfort, and to facilitate the timely removal of harmful gases such as waste heat and smoke in the workshop.

2. Meet the air quality requirements of the production process: Air filter cotton is generally used in conjunction with blowers, air compressors, gas turbines, oxygen generators, etc. to ensure the removal of coarse dust particles, protect high-speed rotating mechanical parts from wear, prevent process equipment from being covered or blocked by dust, purify dry airflow, and ensure product quality, such as film developing process.

3.Meet the special requirements of clean rooms and sterile environments: The demand in this field is growing, requiring high cleanliness. Rooms involving precision machinery, high-purity materials and sterile environment filtration require multi-stage purification.