01

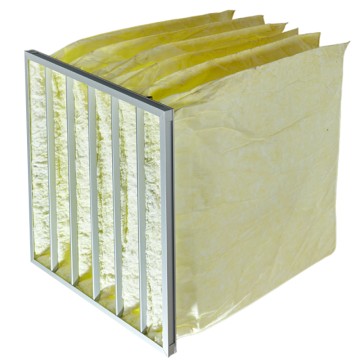

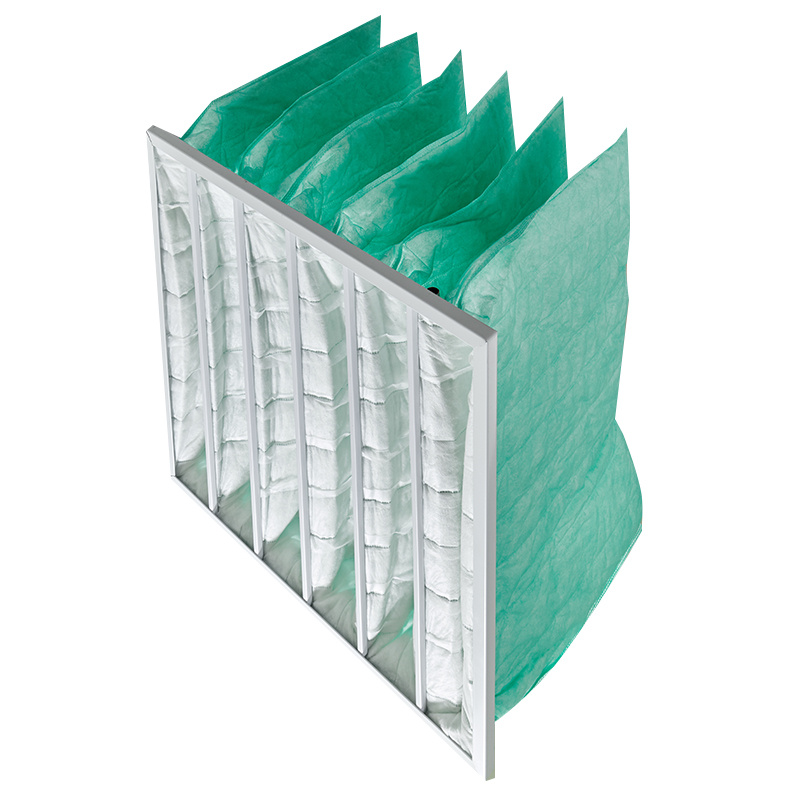

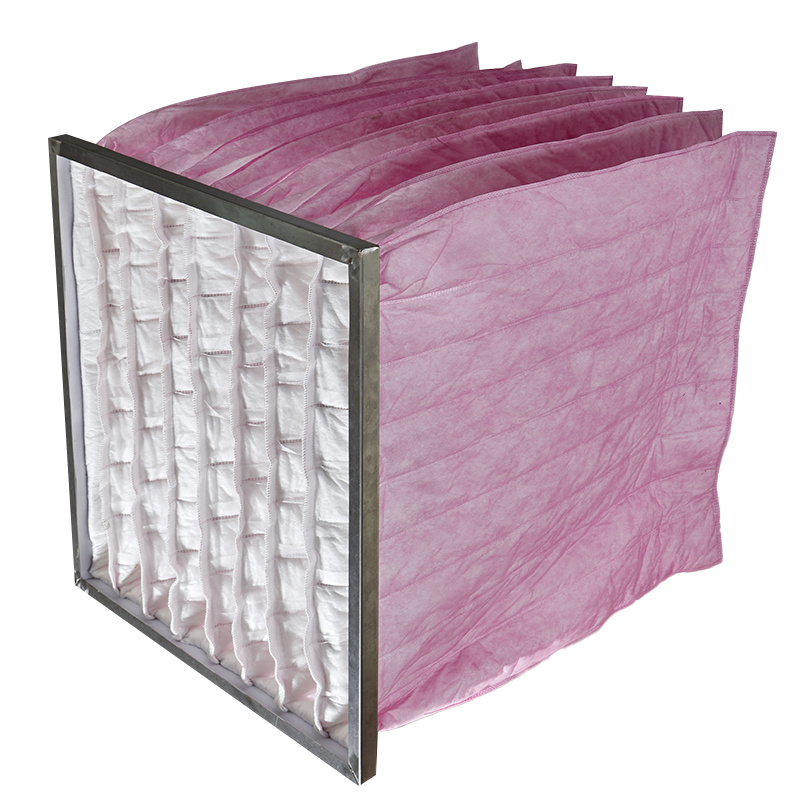

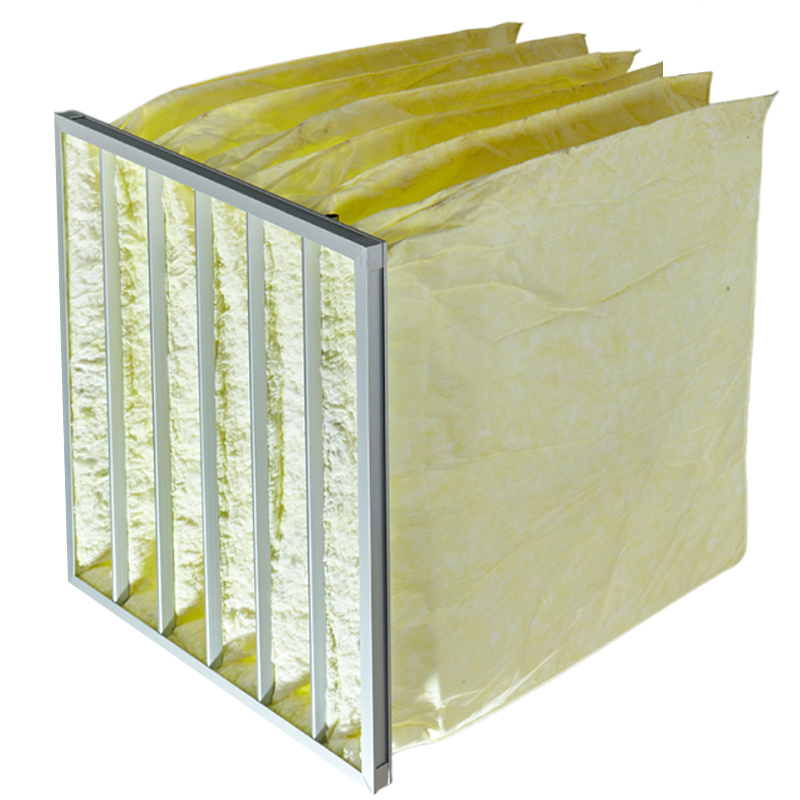

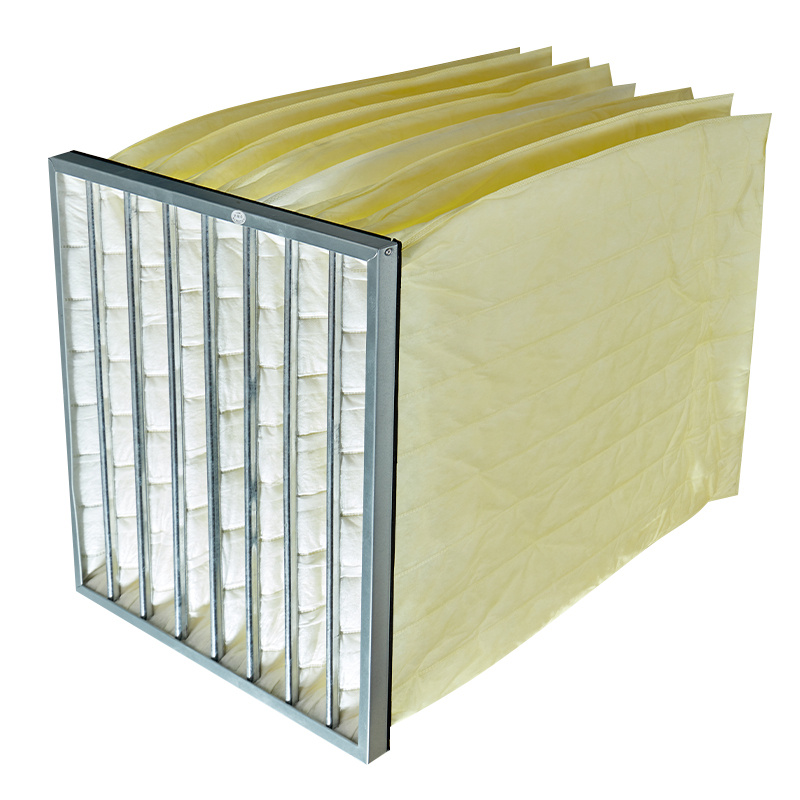

Non-Woven Synthetic Pocket Filter

Main Features

Excellent filtration performance: These filters effectively capture dust and particles, ensuring the output air is clean and free of contamination. This is especially important in environments where air quality is critical, such as paint shops and industrial environments.

High dust holding capacity: Non-woven synthetic bag filters are able to hold large amounts of dust, thereby extending the life of the filter and reducing the frequency of replacement. This feature not only saves costs but also minimizes downtime associated with filter replacement.

Low Resistance: Designed to maintain low airflow resistance, these filters can improve the energy efficiency of ventilation and air conditioning systems. By allowing air to flow freely, they help reduce energy consumption, thereby reducing operating costs.

Good air tightness: The filter ensures minimal air leakage, thereby improving the overall efficiency of the filtration system. This tight seal is essential to maintain optimal performance and ensure that all air passes through the filter media.

Durable Construction: The high strength of the filter bags prevents breakage or detachment, ensuring long-term reliable performance. This durability is critical in harsh environments where filters are susceptible to wear.

Silicon-free design: These filters are suitable for applications where silicone contamination is a concern, such as painting and coating processes. This feature helps prevent defects in the finished product due to contact with silicone.

Standard Compliance: Non-woven synthetic bag filters meet EN779-2012 and ISO 16890-2016 test standards, ensuring high-quality filtration performance. Compliance with these standards ensures that the filters meet stringent industry requirements.

Multiple Applications: These filters have a wide range of uses and can effectively filter tiny particles in the air intake system of the paint spray booth, remove dust on the coating equipment, and perform secondary filtration in high-quality coating systems and baking equipment.

Customization Options: Available in a variety of formats including mats or mats with frames, these filters can be customized to specific installation requirements. This customization ensures that users can find the right product for their system.

Specific applications

Secondary Filtration: These filters are ideal for use in secondary or back-end filtration systems in a variety of ventilation and air conditioning units to enhance the overall filtration process.

Dust Filtration: Effectively removes dust from paint shops and equipment, ensuring a cleaner working environment and reducing the risk of contamination.

Improved Air Quality: By capturing particulate matter and reducing airborne pollutants, these filters significantly improve air quality in industrial environments, contributing to a healthier workplace.

In summary, non-woven synthetic bag filters are an essential component in maintaining air quality and efficiency in a variety of industrial applications. Their reliable filtration capabilities, coupled with durability and energy-efficient design, make them a valuable investment for businesses looking to improve operational performance and create a healthier work environment. By using these filters, companies can ensure cleaner air, reduce maintenance costs, and comply with industry standards, ultimately improving productivity and safety.

Specification

| Filtration Grade | Dimensions (mm)(W*H*D) | No. Of bags | Filtration Area(㎡) | Rated Air Volume | I.N.P(Pa) | F.N.P(Pa) Recommended |

| 35%(G4) | 287*595*600 595*595*600 |

4 8 |

2.85 5.71 |

1800 3600 |

40 45 |

350 |

| 45%(M5) | 287*595*600 595*595*600 |

4 8 |

2.85 5.71 |

1800 3600 |

45 50 |

350 |

| 65%(M6) | 287*595*600 595*595*600 |

4 8 |

2.85 5.71 |

1800 3600 |

50 65 |

400 |

| 85%(M7) | 287*595*600 595*595*600 |

4 8 |

2.85 5.71 |

1800 3600 |

65 75 |

400 |

| 90%(M8) | 287*595*600 595*595*600 |

4 8 |

2.85 5.71 |

1800 3600 |

75 85 |

400 |

| 95%(M9) | 287*595*600 595*595*600 |

4 8 |

2.85 5.71 |

1800 3600 |

85 95 |

400 |

| Note: Special Size Available Upon Request. | ||||||